Discussions about bicycle crank length have been a fairly hot subject recently. There's a trend in TT/Tri circles to use shorter than "normal" crank lengths. This is done to allow folks to either open up the distance between their torso and leg at the top of the pedal stroke (to be better able to produce power) and/or allow them to lower the angle of their torso relative to the ground in an attempt to get more aerodynamic. Sometimes it's done for both. One thing that is commonly brought up is questions about how using shorter (or longer) than normal cranks affects sustainable power output. Does it...or not?

There's a lot of data out there showing that wide variations in crank length do not have significant effects on power output, such as the work done by Jim Martin at the University of Utah, summarized here:

http://www.plan2peak.com/files/32_article_JMartinCrankLengthPedalingTechnique.pdf

From that presentation, "170mm cranks would compromise the power output of the shortest and tallest riders by AT MOST 0.5%. For example 6 watts out of 1200"

Another takeaway: "Crank length and pedaling rate influence metabolic cost and efficiency only by influencing pedal speed."

How can that be? Doesn't it logically make sense that for an optimum setup, a person needs a crank length proportional to their leg length? For example, there are websites out there that claim to identify the "ideal" crank length for a given person (

http://www.nettally.com/palmk/crankset.html). However, one thing that most folks miss on that site is that the lengths of cranks recommended with that method uses an underlying assumption with no apparent basis, i.e.

"The standard crank length of 170mm is optimum for a cyclist with a 31-inch inseam." The entire method is anchored in that assumption...and yet, the Martin study summary I linked to above shows that power production is relatively unaffected over a wide range of crank lengths for a wide range of leg lengths. Is there an optimum? Perhaps...but, even if there is, the Martin data shows that varying from that optimum (even by relatively large amounts) doesn't appreciably affect power output.

But, doesn't a shorter or longer crank affect your "leverage"? Sure...but that difference in leverage can be compensated for elsewhere in the drivetrain. The crank isn't the ONLY lever between your foot and the ground. The gears themselves, along with the rim and tire diameter are also "levers", which can be varied. One thing to keep in mind is that physiologically, our muscles have a preferred shortening speed, which results in a preferred foot speed at the pedal. I'm not talking about cadence...I'm talking about the tangential velocity that the foot travels at during the power production (i.e. downstroke) phase of the pedal cycle.

The Challenge:

A little over a month ago, in a discussion on the Wattage Google Group about the effects of differing crank lengths, the following was posted in response to the idea that changing crank lengths could be "compensated" by varying gearing selections:

"The gearing argument has been raised many times. It's usually raised and

argued a lot by people not on the big side of the spectrum, ie people

that are already on somewhat ideal cranks.

My counter argument is this:

If

you are riding say 170mm cranks and you firmly believe that gearing can

wholly make up for cranks of the wrong size. I encourage you to take

the "Pepsi Challenge" that challenge is this:

1: Go TT up your

favorite 15 minute or longer hill at LT or greater power (by HILL I mean

something with average grade 6% or greater) with your current setup and

time it a few times.

2: Then put on crank arms that are only 87.5%

in length of your current setup. That would be 148.75mm if you are

currently riding 170s. You now have my proportional experience setup of

me riding 175mm cranks.

Take your own medicine and re-gear

appropriately. Now ride that setup for a few weeks and go TT up your

favorite hill a few more times and time it.

If you can show me you can do the same time with your medicinal gearing going full tilt, then I'll happily eat some humble pie.

I've

offered that challenge for a few years now, and suprisingly enough NO

ONE HAS TRIED IT. Go figure. News flash, I and many other long legged

people that have actually taken that "pepsi challenge", have come to the

very real conclusion the longer arms are faster. Now we can quibble

over why they are, but that's kinda irrelevant, fact is they are.

So

I really challenge you or anyone else who is of normal size to take

that challenge and see what it's REALLY like to be riding something so

far out of what for what your body needs. Been over 5 years since I

first offered that challenge, and I'm still waiting for someone of

"normal" size to try it out...patiently.

cheers,

-kieran"

https://groups.google.com/forum/#!msg/wattage/kVyNPWvOq7M/iNP0DIn-QWUJ

Not being one to shy away from a challenge like that...especially since the one doing the challenging is someone I know...I decided to take it up. Luckily, I have a friend (Greg Steele, of Beehive Bicycles in Salt Lake City

http://www.beehivebicycles.com/) who let me borrow a set SRM cranks with the adjustable length option.

These cranks allow for an adjustment range of 150-190mm. To do the testing, I decided to use the first 2 miles of a local ~8% average grade hill. From the Kirby Palm "method", I used as the first test a setting of 175mm since that's what his formula claims is the "optimum" for my 32" inseam (as measured per his instructions). In order to ensure that my lowest gearing was as equivalent as possible, I chose a 12-25 cassette for use the 175mm cranks. Since the crank length was pretty close to my normally used 170mm, all I did for adjustments was lower the saddle slightly. After setting everything up, off I went to the hill and give it "full stick" for my baseline. Here are the results:

Time = 12:50, Power = 289W, Cadence = 73 rpm, HR = 170bpm

For the short crank length, I wanted to use something that was equivalent, or below, the "87.5% below optimum" in the challenge above. For that, I chose 150mm, which is actually only 85.7% of the "optimum" 175mm length. In order to assure nearly equivalent low gearing, I chose a 12-30 cassette to pair with my 39T small ring.

Now then, when making such a large change in crank length, it's important to make sure to maintain the relationships between the saddle, the bars, and the foot during the "power", or downstroke part of the pedal cycle. As such, when I adjusted the crank length from 175mm down to 150mm, I did 2 things with the saddle. First, I raised the seatpost such that the distance between the portion of the saddle I rest my sitbones on and the pedal at max extension was the same distance, but I ALSO moved the saddle rearward on the rails so that in the end it was a full 25mm further rearward relative to the center of the BB than when the cranks were set at 175mm. This was done to keep the relationship between my lower leg and the pedal equivalent at the "3 O'clock" portion of the pedal stroke. Because of the movement in the saddle (both up and rearward), that also meant I need to move the bars the same directions to keep the bar to saddle relationship as close as possible. Luckily, I had a stem handy that was short enough, and with a high enough rise so that I could do this with a fairly simple stem swap. It wasn't the exact dimensions required, but it was close enough. Shown below is an overlay of the 2 setups.

So...after making the setup change a few days after the baseline run, I then ventured out to the test hill and with the only "accomodation" being the ~15 minute ride over there, I did a run with the 150s. Here are the results for that:

Time = 12:50, Power = 286W, Cadence = 84 rpm, HR = 171bpm

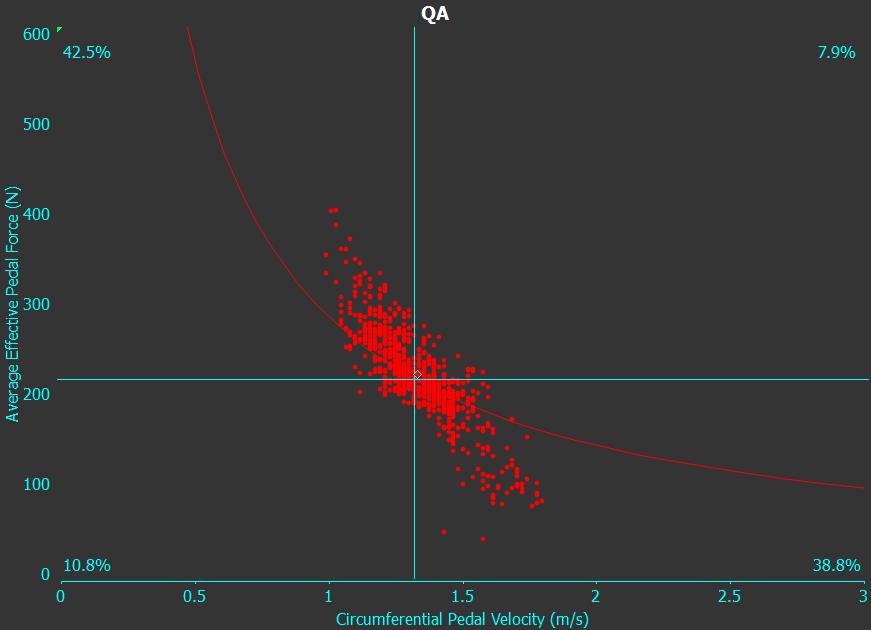

Or...basically the SAME time, power, and HR as the 175mm crank length run. As expected, the cadence increased so that my tangential pedal speed and average pedal force were the same. This can be easily seen with a

Quadrant Analysis plot of each run.

175mm Crank QA

150mm Crank QA

Pretty much identical, no?

Anyway...so what does this all mean? It means that determining an "optimal" crank length for bicycling isn't very important. Instead of worrying about it from that standpoint, just understand that a wide range of lengths are acceptable, and use it as a "lever" (pun intended) for other things, such as fitting issues. One thing you might want to be wary of is going too large, in that that actually can start causing problems at the top of the pedal stroke and/or prevent the most aero position for a given event. It's somewhat hard to go "too small" (within reason) on crank length...just make sure you're geared adequately for the course profiles.

Oh...and it also means Kieran needs to eat some "humble pie"....nom, nom, nom ;-)